What is a 3D printing farm?

A 3D printing farm or 3D printing cell is an installation of several 3D printers that are used for manufacturing. This group of printers operate simultaneously and as continuously as possible to increase production rates of printed parts. For a print farm to operate at high efficiency, it is essential to minimize printer downtime.

Uses cases

Short productions

When used for short run or bridge manufacturing, a multi-printer facility delivers substantial cost and time savings compared to outsourcing or traditional production methods, such as injection molding, making limited runs of hundreds of parts accessible

Prototyping

When used for prototyping, having multiple 3D printers facilitates rapid iteration of multi-component designs and allows companies to support multiple design projects and teams without bottlenecks.

Benefits

Boost Production Capacity

Print in Multiple Materials Simultaneously

Redundancy and Reliability

Deployment

In order to automate the printers in our store or makerspace we need all printers to have 1 of the following connections:

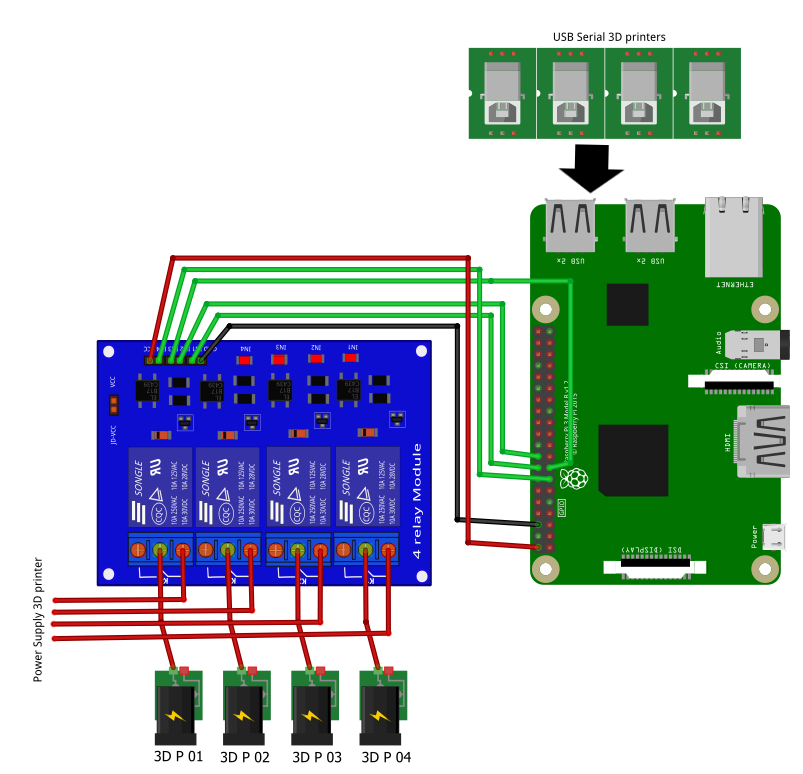

USB Serial

Ethernet

WiFi

Once the connections have been surveyed, we need to know what firmware the printer controller board has, the most common ones are usually:

Marlin

Klipper

Craftbot

This point is important to determine if the printer is going to be controlled by our 3D printing server.

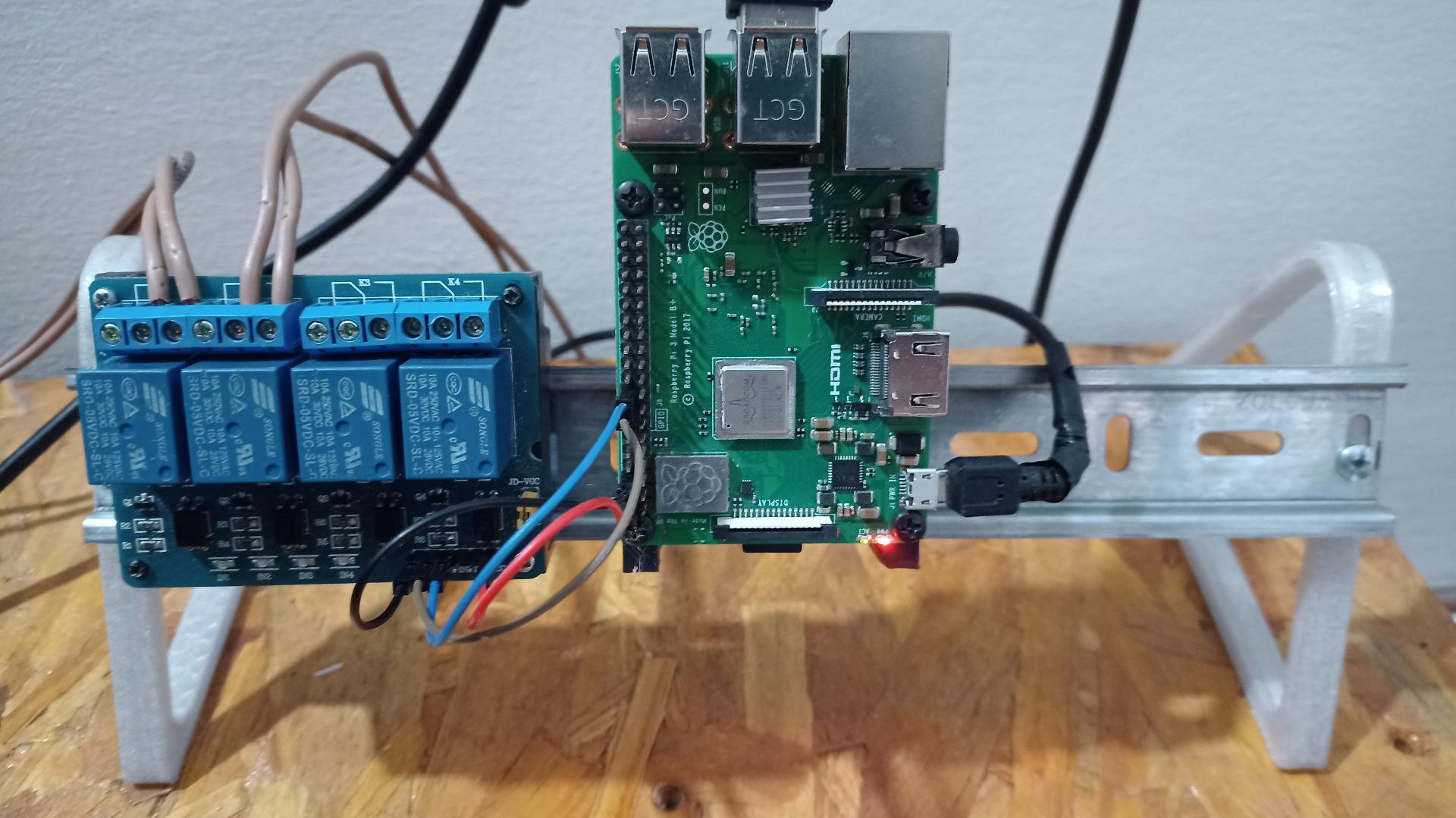

Once we know: connections and firmware, we can move forward with the electronic deployment using a Raspberry Pi 3/4 and a relay 4/6/8.

In the next part, we will see how to install a 3D printing system that manages all the printers in our store or makerspace.